What is CNC Machining? Definition and advantages

What is CNC Machining? Definition and advantages.

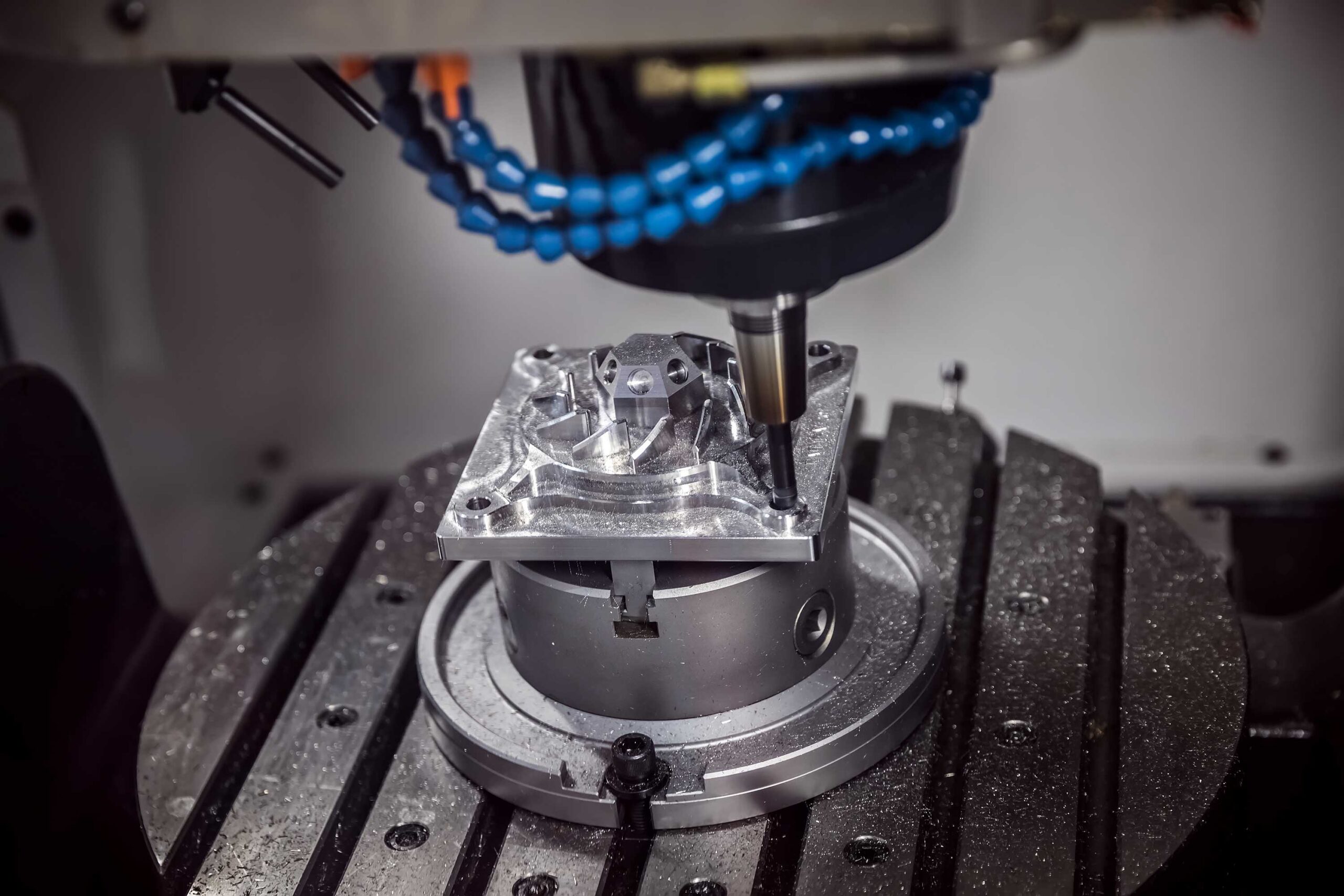

CNC machining, which stands for Computer Numerical Control machining, is a manufacturing process that involves the use of computer-controlled machines to produce precise and complex parts from a variety of materials.

Advantages of CNC machining:

1. Precision: CNC machines can produce parts with high precision and accuracy, ensuring that parts meet exact specifications.

2. Efficiency: CNC machines can operate continuously, 24/7, which can increase productivity and reduce lead times.

3. Consistency: CNC machines can produce identical parts with consistent quality, reducing the risk of errors or defects.

4. Flexibility: CNC machines can be programmed to produce a wide range of parts, making them suitable for a variety of applications.

Tools used in CNC machining:

1. Cutting tools: CNC machines use a variety of cutting tools, including drills, mills, and lathes, to shape and form parts.

2. Workholding devices: CNC machines use workholding devices, such as clamps and vises, to hold the part in place during machining.

Precision CNC Machining. Processes and more:

Precision CNC machining is a manufacturing process that utilizes computer-controlled machines to produce precise and complex parts. There are several processes involved in CNC machining, including:

1. Turning: Turning is a process that involves rotating a workpiece while a cutting tool removes material to create a cylindrical shape.

2. Milling: Milling is a process that involves removing material from a workpiece using a rotating cutting tool.

3. Drilling: Drilling is a process that involves creating holes in a workpiece using a drill bit.

4. Grinding: Grinding is a process that involves using an abrasive wheel to remove material from a workpiece to create a smooth surface.

5. EDM (Electrical Discharge Machining): EDM is a process that uses electrical sparks to remove material from a workpiece.

6. Laser cutting: Laser cutting is a process that uses a high-powered laser to cut through materials.

Precision CNC machining can be used to produce parts from a variety of materials, including metals, plastics, and composites. Some common materials used in CNC machining include:

1. Aluminum: Aluminum is a lightweight and corrosion-resistant material that is commonly used in aerospace and automotive applications.

2. Stainless Steel: Stainless steel is a strong and durable material that is commonly used in the medical and food industries.

3. Titanium: Titanium is a lightweight and strong material that is commonly used in aerospace and medical applications.

4. Plastics: Plastics, such as ABS, polycarbonate, and nylon, are commonly used in CNC machining due to their versatility and ease of machining.

Overall, CNC machining offers a range of advantages, including precision, efficiency, consistency, and flexibility, making it a popular manufacturing process for a variety of industries and applications.