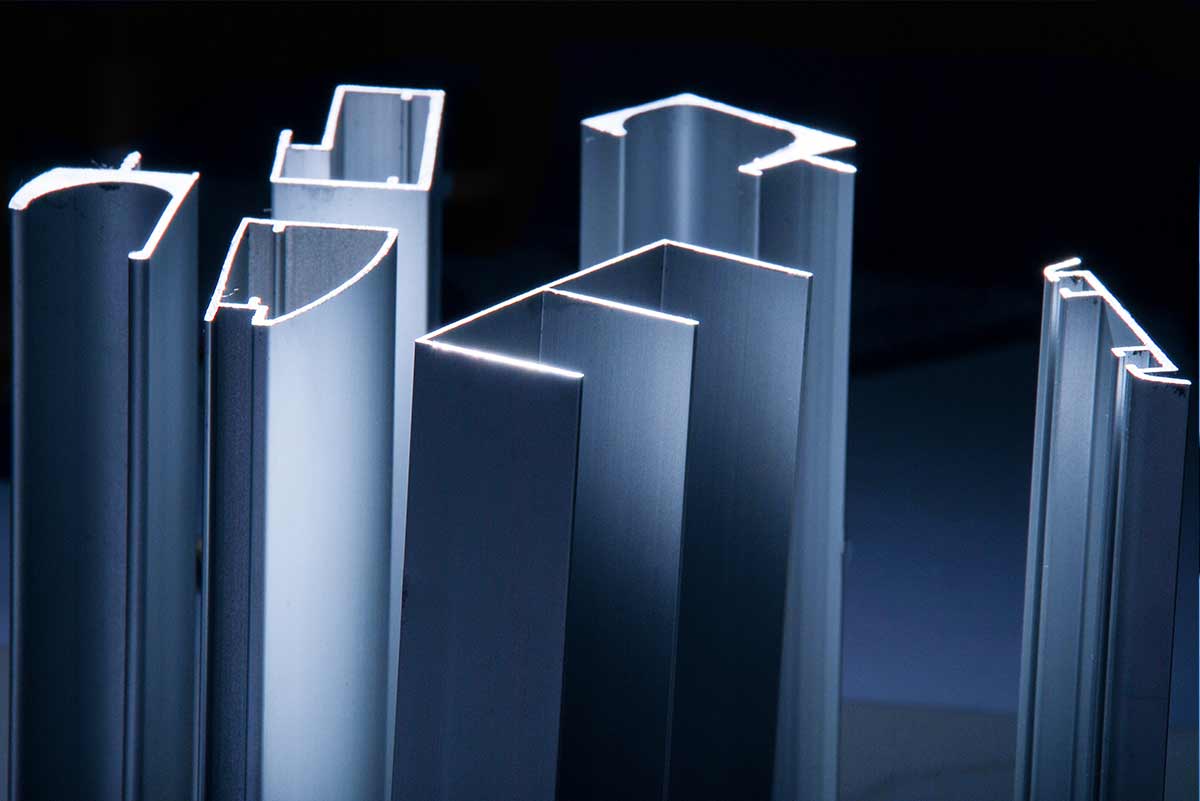

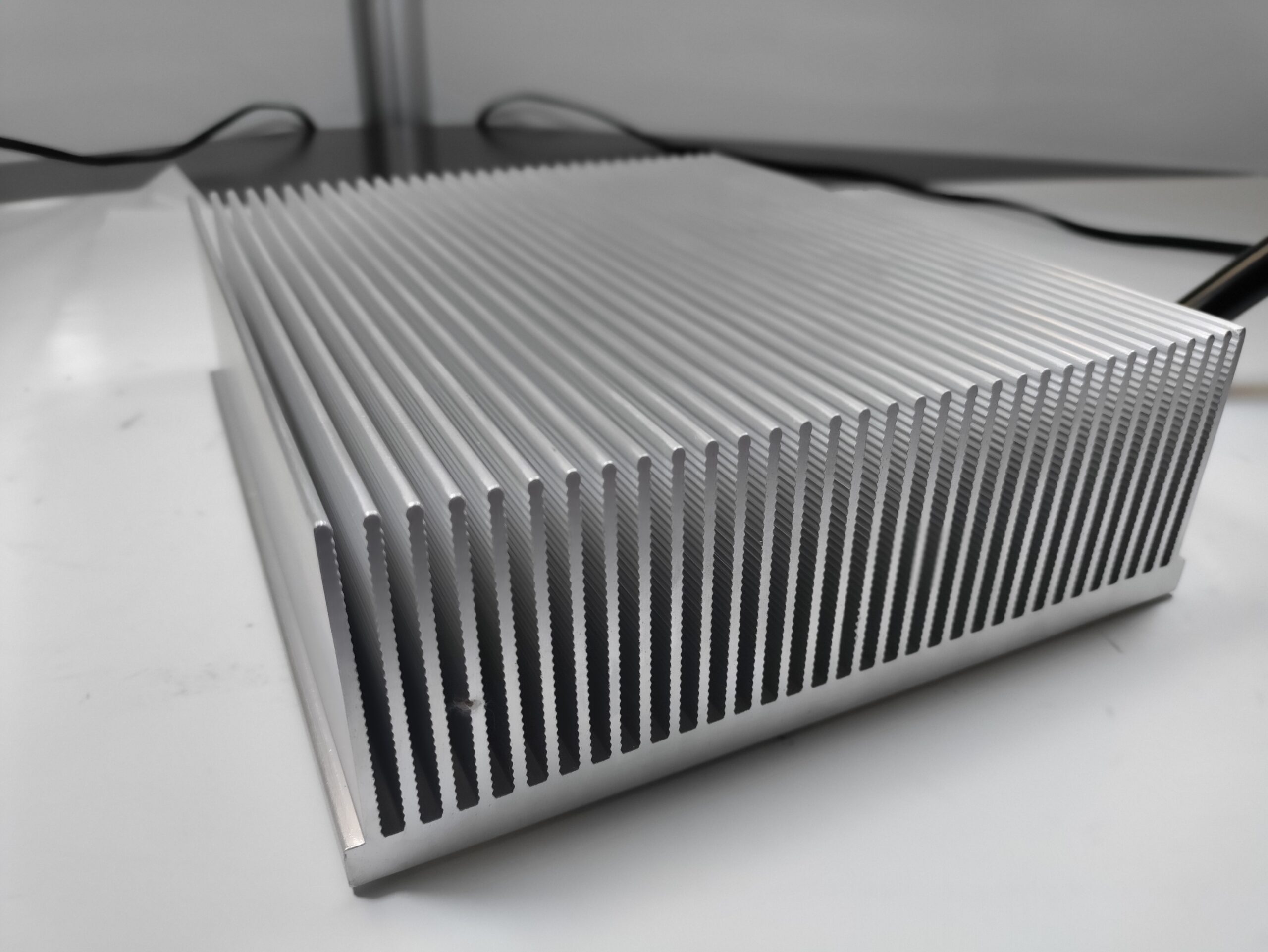

Cooling Source provides a wide range of conventional extrusion profiles. We can ship cut-to-length or a 6-foot-long bar. To make a straight or cross-cut completed Aluminum Extrusion Profile heatsink, an aluminum block is pushed (extruded) through a die. As a result, we can offer a variety of convection cooling solutions for high-power components. Furthermore, we can produce sophisticated, high-quality aluminum extrusion fins to fit your needs.

Quality Assurance

Cooling Source will meet or exceed all applicable Customer and other standards. We will try to surpass consumer expectations. Therefore, we will continuously engage and challenge our outstanding employees to enhance each process and system.

Top management is responsible for enforcing the quality policy:

The CSI mission

Consists of a commitment to meet criteria and continuously improve the efficacy of the quality management system.

Establishes and reviews quality targets within a framework.

Within the company, there is clear communication.

We constantly assess appropriateness.

Engineering Assistance

Our engineers use advanced 3D modeling as part of their design work. In addition, to optimize your heat transfer project, we use cutting-edge CFD tools. Furthermore, we offer our customers a complete cooling solution to satisfy their individual needs in a timely and cost-effective manner.

Call or email us today to discuss your choices. We are convinced that you will enjoy our goods, competitiveness, engineering support, and customer service during and after the sale.

Advantages of extrusion when CNC Machining

Using aluminum extrusion with precision CNC machining offers several benefits, including:

1. Design flexibility: Aluminum extrusion allows for the creation of complex shapes and profiles that are difficult or impossible to achieve with traditional machining methods. This makes it possible to create parts and components with unique designs and features.

2. Cost-effective: Aluminum extrusion is a cost-effective manufacturing process that can produce large quantities of parts quickly and efficiently. CNC machining can then be used to add precision details to the extruded parts.

3. High strength-to-weight ratio: Aluminum is a lightweight metal that is also strong and durable. This makes it an ideal material for parts and components that need to be both strong and lightweight.

4. Corrosion resistance: Aluminum is naturally resistant to corrosion, making it ideal for use in environments where exposure to moisture or other corrosive elements is a concern.

5. Customization: Aluminum extrusion can be customized to meet specific requirements, such as size, shape, and finish. CNC machining can then be used to add precision details to the extruded parts.

6. Consistency: Aluminum extrusion and CNC machining are highly repeatable processes, ensuring that each part or component is consistent in size, shape, and quality.

Overall, using aluminum extrusion with precision CNC machining offers a cost-effective and efficient way to produce high-quality parts and components that are strong, lightweight, and corrosion-resistant. This makes it an ideal choice for a wide range of industries,

including aerospace, automotive, and consumer goods.

Our Partners:

ambayarea.com

thomasnet.com

Our Contact Us:

Email Us