CNC MANUFACTURING

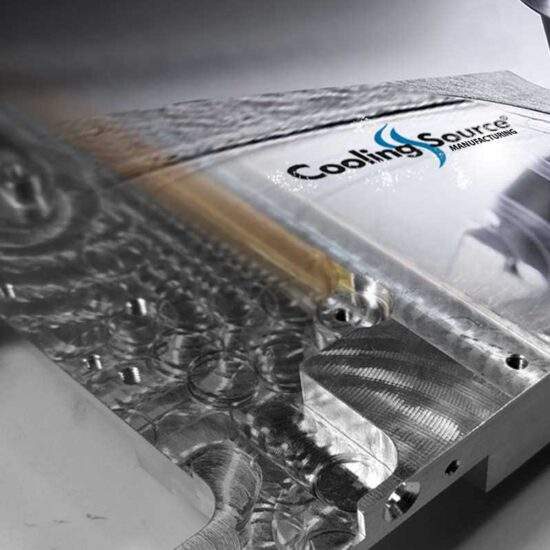

CNC manufacturing entails using computer-controlled machines to remove material from a workpiece. Quick-turn manufacturing is defined as the ability to produce parts quickly and efficiently, often with short lead times. Competitive pricing is essential in the manufacturing industry and allows Cooling Source to offer parts made at a lower cost than its competitors. Process control refers to the ability to monitor and adjust the manufacturing process to ensure consistent quality and efficiency. Together, these elements can help Cooling Source produce high-quality products at a competitive price. Also, we maintain control over the manufacturing process, which utilizes computerized controls and machine tools to produce precise and complex parts from various materials. We use computer-aided design (CAD) software to create a digital model of the desired part, which we then translate into instructions to control the movement and operation of the CNC machine.

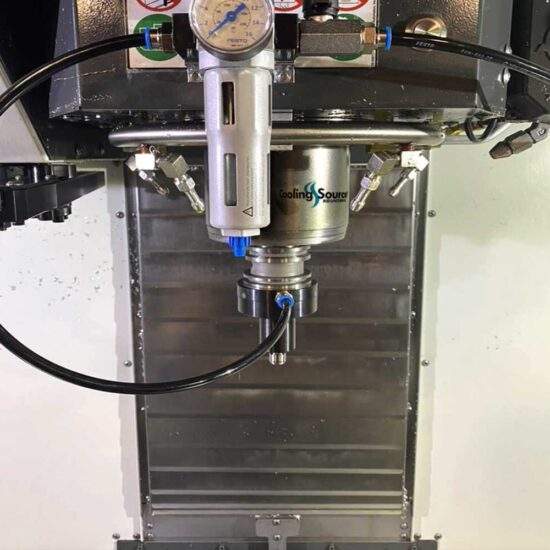

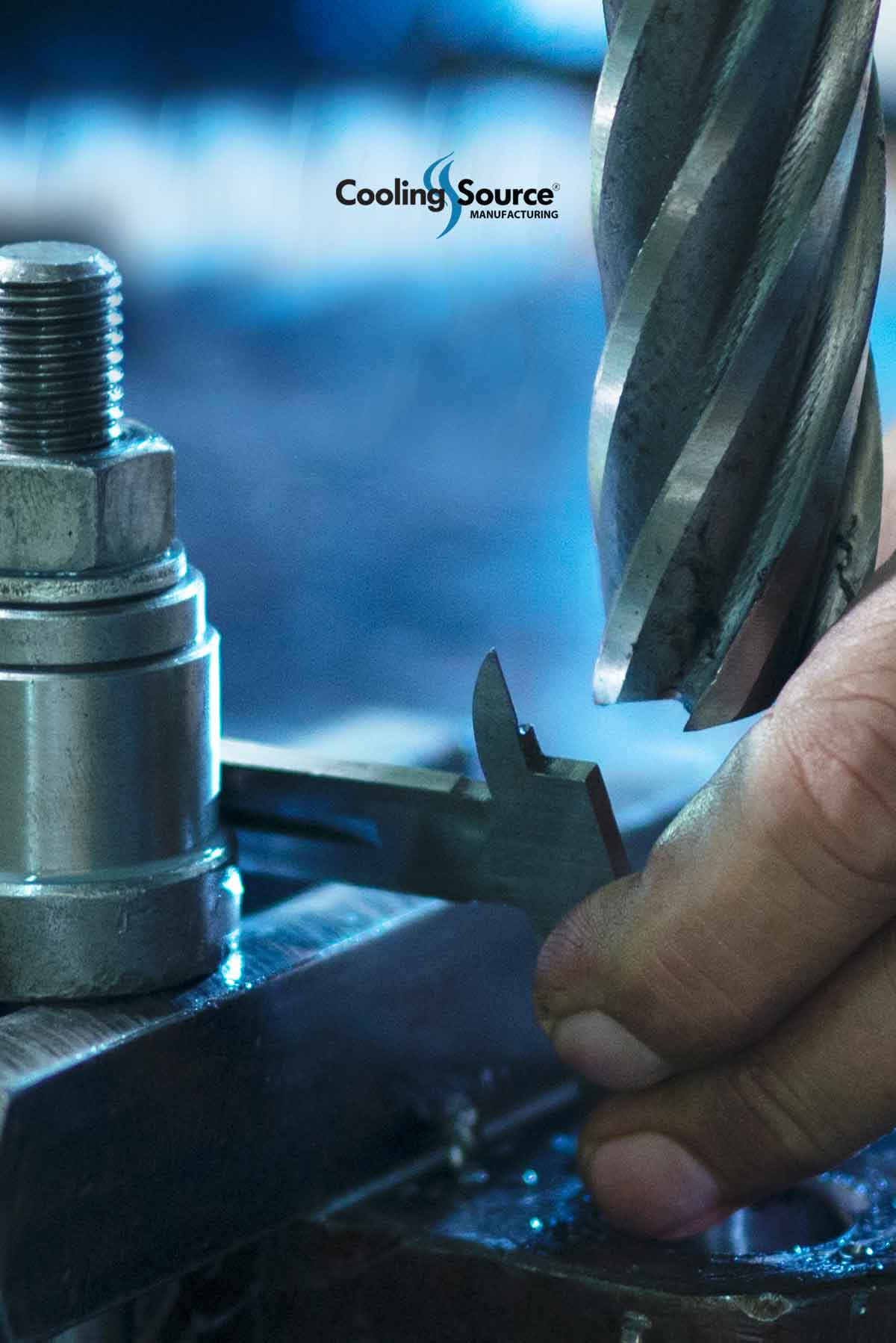

The computer program precisely controls the axes and cutting tools of the CNC machine, typically a mill, lathe, or router. The machine follows the instructions provided in the program to remove material from the workpiece and shape it according to the design specifications. The CNC machine can perform a wide range of operations, including cutting, drilling, milling, turning, and grinding.

We offer several advantages over conventional manual machining techniques by providing high precision and repeatability, as the computer-controlled machines can consistently produce parts with tight tolerances. CNC machines also offer increased efficiency and productivity since they can operate continuously and automatically, reducing the need for manual intervention. Furthermore, our CNC manufacturing capabilities allow for complex designs and intricate features that would be challenging or impossible to achieve manually.

This technology finds extensive applications in various industries, including automotive, aerospace, electronics, medical devices, prototyping, and many others. It enables the creation of custom parts, rapid prototyping, and mass production of components with high accuracy and consistency.

Cooling Source has a strong reputation for delivering high-quality parts and components on time. We have invested in the latest technology and equipment to ensure that we can provide you with precision manufacturing services that meet the needs of a variety of industries.

To maintain our position as a leader in CNC manufacturing, it’s important to stay up-to-date with the latest advancements in technology and techniques. We work hard to build strong relationships and provide exceptional customer service to ensure that they continue to choose Cooling Source for their CNC manufacturing needs.

We provide custom CNC manufacturing services in Seattle, Portland, Oakland, San Francisco, Livermore, Santa Clara, Silicon Valley, San Jose, Los Angeles, Orange County, San Diego, Sacramento, Denver, Salt Lake City, Dallas, Austin, Houston, Phoenix, Boston, New York, Chicago, Tampa, Miami, Minneapolis, Canada, Europe, Asia, and Australia.

Globally Competitive / High Quality

Globally competitive high-quality CNC machining through efficient engineering process.

CNC MANUFACTURING ENGINEERING SUPPORT

Locally based, experienced CNC Manufacturing & design engineers working closely with you to ensure the lowest cost and highest efficiency solutions.

CNC MANUFACTURING SERVICES

Quality Control

Highest quality 5-Axias CNC Manufacturing through experience and certification.

Turnkey Assembly

Lowest cost box build provides the highest integration level and CNC Machining and Manufacturing for complete solutions.

5-Axis CNC manufacturing, milling, turning, EDM, tube bending, sheet metal fabrication, aluminum extrusion and full line of services, Seattle, Portland, Oakland, San Francisco, Livermore, Santa Clara, Silicon Valley, San Jose, Los Angeles, Orange County, San Diego, Sacramento, Denver, Salt Lake City, Dallas, Austin, Houston, Phoenix, Boston, New York, Chicago, Tampa, Miami, Minneapolis, Canada, Europe, Asia, Australia.