Turnkey Assembly

Turnkey assembly has several advantages and benefits, including:

1. Timesaving: Turnkey assembly saves time as all the components are assembled in one place, eliminating the need for multiple suppliers and reducing lead times.

2. Cost-effective: Reduces costs as it eliminates the need for multiple suppliers, reduces transportation costs, and minimizes the risk of errors in the assembly process.

3. Quality control: Ensures consistent quality as all the components are assembled in one place, and the assembly process is closely monitored.

4. Flexibility: Offers flexibility as it can be customized to meet specific requirements, and changes can be made quickly and easily.

5. Single point of contact: Provides a single point of contact for all assembly needs, simplifying communication and reducing the risk of miscommunication.

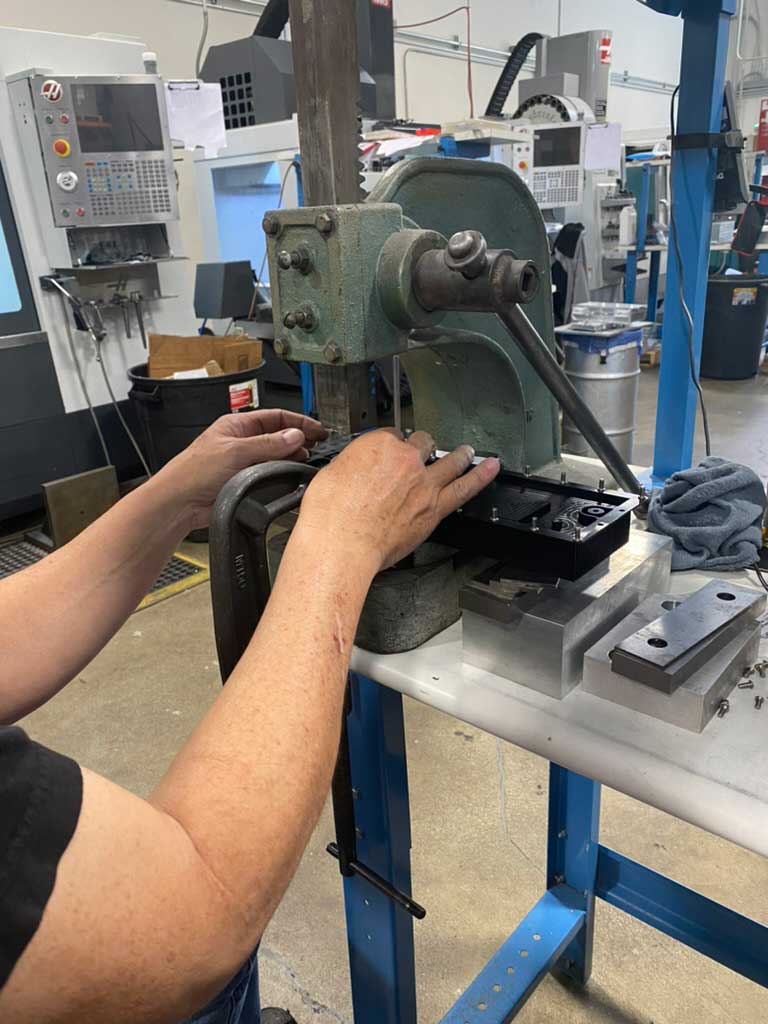

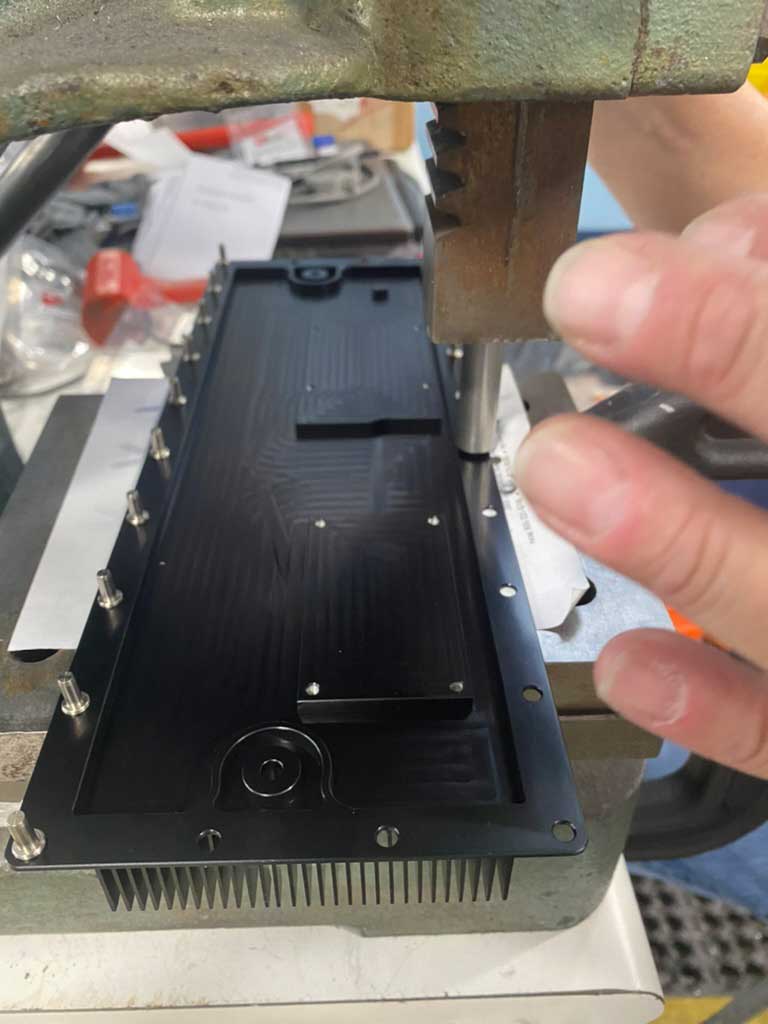

6. Expertise: Is carried out by experts who have the necessary skills and knowledge to assemble complex products, ensuring that the final product meets the required specifications.

Turnkey assembly is a term used in the manufacturing industry to describe a complete product or system that is ready to use without any additional assembly or modification. Here are some common types of turnkey assemblies:

1. Electrical assembly: Includes all the necessary electrical components, wiring, and controls needed for a specific application or system.

2. Mechanical assembly: Includes all the necessary mechanical components, such as gears, motors, and bearings, needed for a specific application or system.

3. Hydraulic assembly: Includes all the necessary hydraulic components, such as pumps, valves, and cylinders, needed for a specific application or system.

4. Pneumatic assembly: Includes all the necessary pneumatic components, such as compressors, regulators, and actuators, needed for a specific application or system.

5. Custom assembly: This type of assembly is designed and built to meet the specific needs and requirements of a customer’s unique application or system.