CNC Turning

Let Cooling Source Manufacturing bring your product idea to life with our top-tier services. We offer cost-effective CNC turning services without compromising turned parts’ quality, accuracy, and precision.

CSI facility features various CNC machines of different sizes and capabilities to meet manufacturing requirements. In addition, our team of highly qualified engineers and machinists work with our quality control experts. As a result, Cooling Source manufactures your parts per print and ensures your satisfaction in a timely manner.

What is CNC Turning?

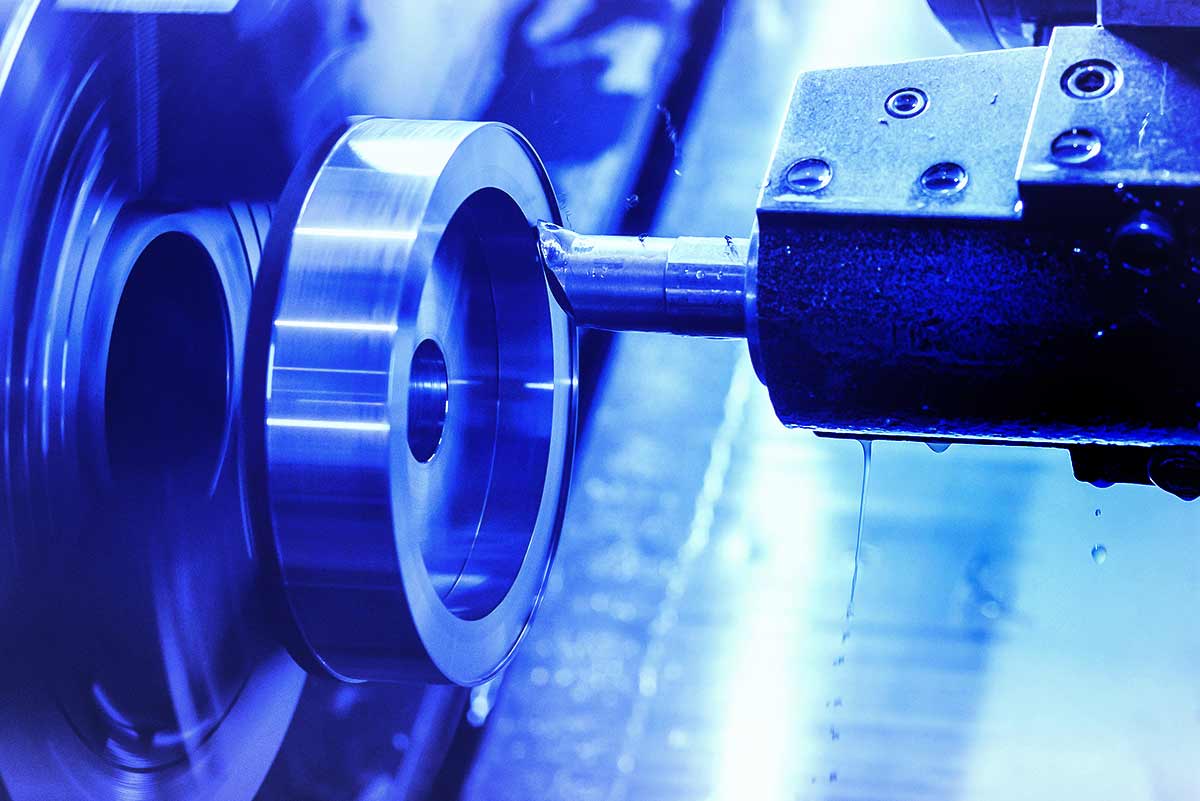

It is a manufacturing process that relies on a computer program to remove portions of material from a workpiece and create desired parts. Of course, the process starts with the 3D CAD model of your desired part before converting it into G-code (computer program) using computer-aided manufacturing (CAM) software. Later, the G-code then automates the cutting tool and workpiece operation to create your desired shape.

Is quite like the CNC Milling process. However, unlike CNC millingㅡwhich keeps the workpiece fixed as the cutting tool rotates against the cutting tool, a CNC turning machine is held in place as the workpiece rotates against it.

It is a process that manufactures parts by “turning a material” against a fixed cutting tool to form the desired shape

Why CNC Turning?

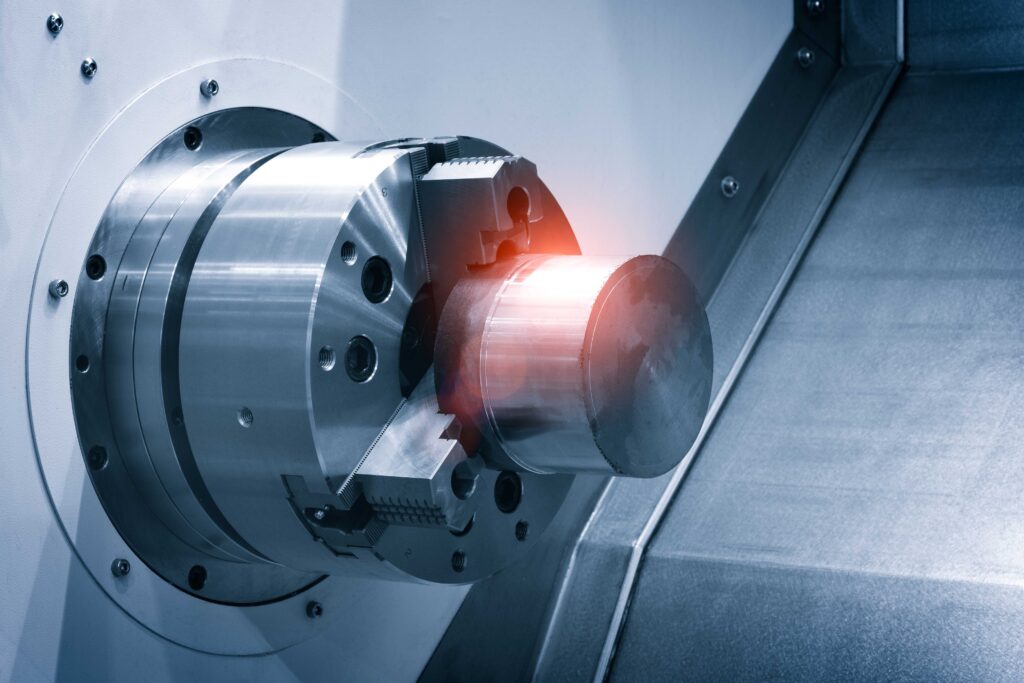

It is ideal for creating symmetrical cylindrical shapes or parts near their axis, for example, a chess pawn, bolts, rivets, ball bearings, and washers. CNC turning also solves some of the manufacturing challenges associated with CNC milling. For example, it allows you to create undercuts or relief grooves easily, whereas CNC milling machines require specialty cutting tools to achieve this.

These machines also allow cutting operations to occur along the 3-, 4-, or 5-axis, allowing you to perform taper turning, knurling, threading, and parting, among other operations. This subtractive manufacturing process is particularly suited for rapid prototyping and low-volume production.

Nevertheless, CNC turning can be used with CNC milling to create high-quality parts accurately while meeting tight tolerances.

Advantages of Cooling Source Manufacturing’s CNC Turning Services<br>

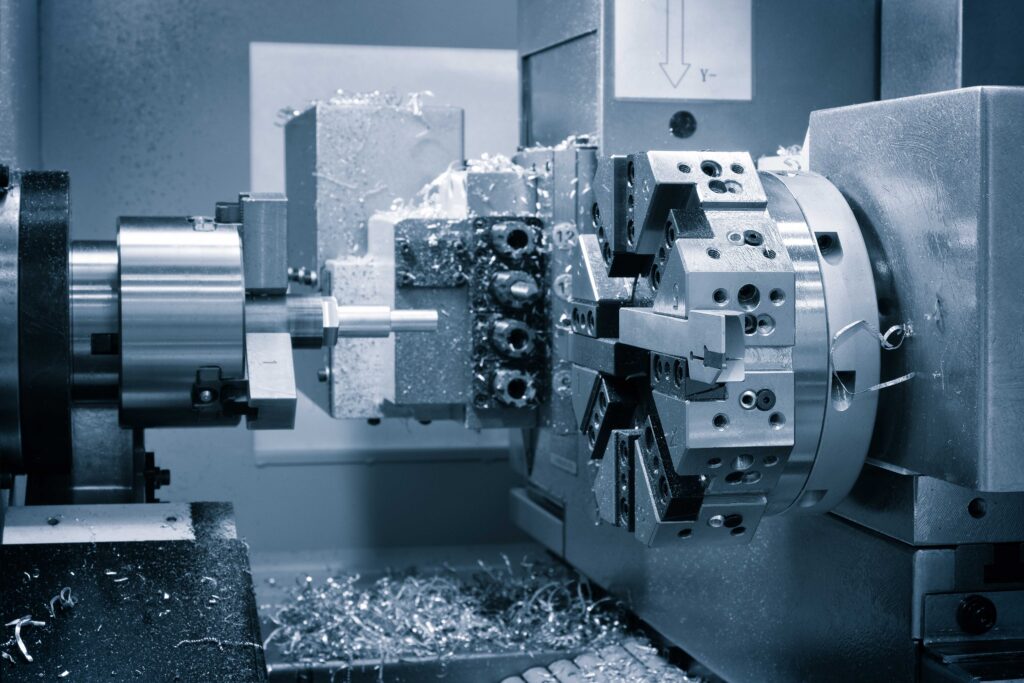

Cooling Source Manufacturing uses state-of-the-art multi-axis these machines are capable of manufacturing parts dimensions up to 400mm (in diameter) while meeting tight tolerance requirements of up to ±0.001mm.

Our highly qualified engineers and machinists work with our dedicated quality control team to ensure that products are done right the first time and satisfy customers’ requirements and standards.

Our engineers and machinists utilize best-in-class software, including SolidWorks, and MasterCAM, to create 3D CAD models that satisfy the design for manufacturing (DFM) criteriaㅡwhich means we design parts for ease of manufacturing.

Competitive prices allow you to complete your product development project cost-effectively.

We are experts in rapid prototyping, and our low-volume CNC turning services can bridge the prototyping and final stages of your product development process.

CNC Precision Turned Parts Material Options

Metals

Aluminum: 2021, 5052, 6061, 6063, 7075, etc.

Steel: 303, 304, 316, stainless steel, tool steel, carbon steel, etc.

Brass

Copper

Special alloys: Kovar, Invar, Titanium, etc.

Plastics

POM

PTFE

PC

PEEK

PET

PEI

PA6CNC Turning Capabilities Overview

Hass Machines

Part dimensions up to 400mm in diameter, 600mm in length

Precision down to ±0.001mm

ISO 9001:2015 certified Quality Management System