oo

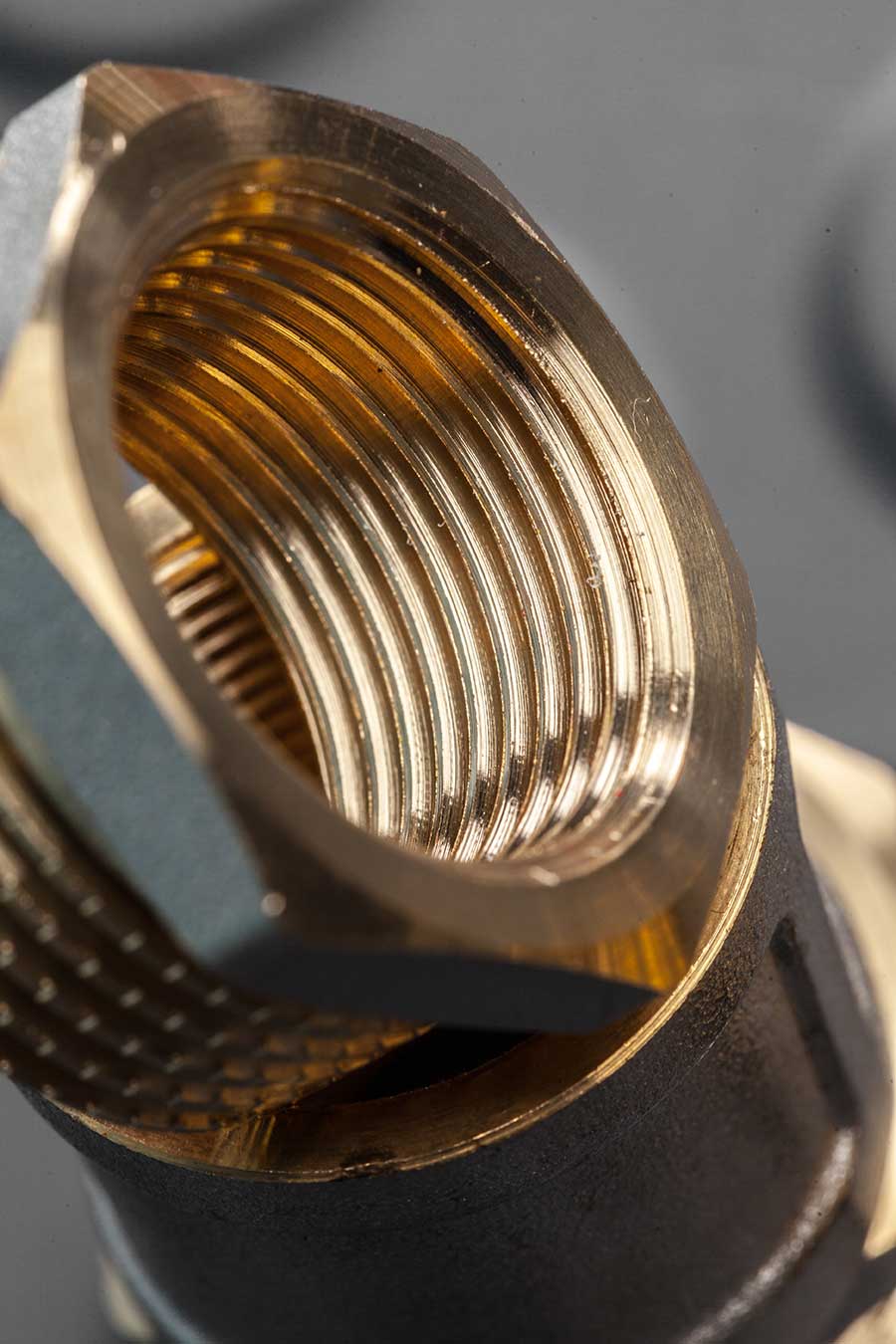

Brass CNC

Brass is a metal alloy composed of copper and zinc. Therefore, Cooling Source frequently works with brass alloys for CNC machining because of its unique qualities. Consequently, Cooling Source manufactures many brass products for various industries due to its versatility.

Precision Machining with brass metal

Precision machining with brass metal involves using advanced machinery and tools to create precise and accurate parts and components. Brass is a popular metal for its excellent machinability, durability, and corrosion resistance.

The precision machining process typically involves several steps, including:

1. Design and engineering: The first step in precision machining is to create a detailed design and engineering plan for machining the part or component. This may involve using computer-aided method (CAD) software to create a 3D model of the part.

2. Material selection: Indeed, Brass is selected per the design requirements.

3. Machining: The machining process involves using advanced machineries, such as CNC lathes and mills, to cut and shape the brass material into the desired shape and size. This process may include drilling, milling, turning, and grinding.

4. Finishing: Surely, it means removing any rough edges or burrs and giving it a smooth, polished surface.

Cooling Source manufactures brass metal for various industries, including aerospace, automotive, medical, and electronics. In addition, our specialists work with brass to create complex parts and components requiring high accuracy and precision, such as gears, valves, and bearings.

Our Partners:

ambayarea.com

thomasnet.com

Our Contact Us:

Email Us