Certifications are Required

When considering working with a CNC machining plant, reviewing the quality standards they go by is recommended. ISO 9001:2015 is a good start.

ISO 9001:2015 is a quality management system that sets the standard. Cooling Source is an ISO 9001-2015 certified manufacturing company, and we rigorously comply with every procedure to ensure high-quality machining services.

CSI conducts regular maintenance and makes sure the CNC machines are calibrated. In addition, we keep a log of our inspections and procedures.

Machining Equipment Type Influences Machined Part Quality

The type of CNC machines used to make a prototype (or production) parts significantly impact the quality of the parts you’ll get. CNC machines are classified by the number of axis they can operate on, for example, 2-, 3-, 4-, and 5-axis CNC machines.

5-axis CNC machines, as one might expect, are more advanced than 2-, 3-, and 4-axis CNC machines. They provide improved relational accuracy, surface smoothness, and the ability to create complicated shapes. Not every job requires 5-axis machining, but it may be the best option if the part is difficult enough.

Cooling Source uses advanced CNC technologies to produce high-quality machined products. But that isn’t the only thing you should look for in a third-party machining vendor!

The technician operating the machine determines the quality of CNC machining.

Indeed Cooling Source CNC operators are experienced and certified. You can count on our team to ship quality parts timely.

Three Types of Inspection Performed by Cooling Source

At various phases of the manufacturing, our team conducts three types of inspections, they are:

Setup Inspection

CSI setup specialists inspect critical dimensions to ensure tolerances are met. Then, they use specialized measuring tools and document the results.

In-process Inspection

Cooling Source uses programmed probes to evaluate essential features and tolerances of a part during the CNC machining process. These probes monitor the operation automatically and modify work coordinates and cutting tools as needed.

Final Inspection in the quality control (QC) department

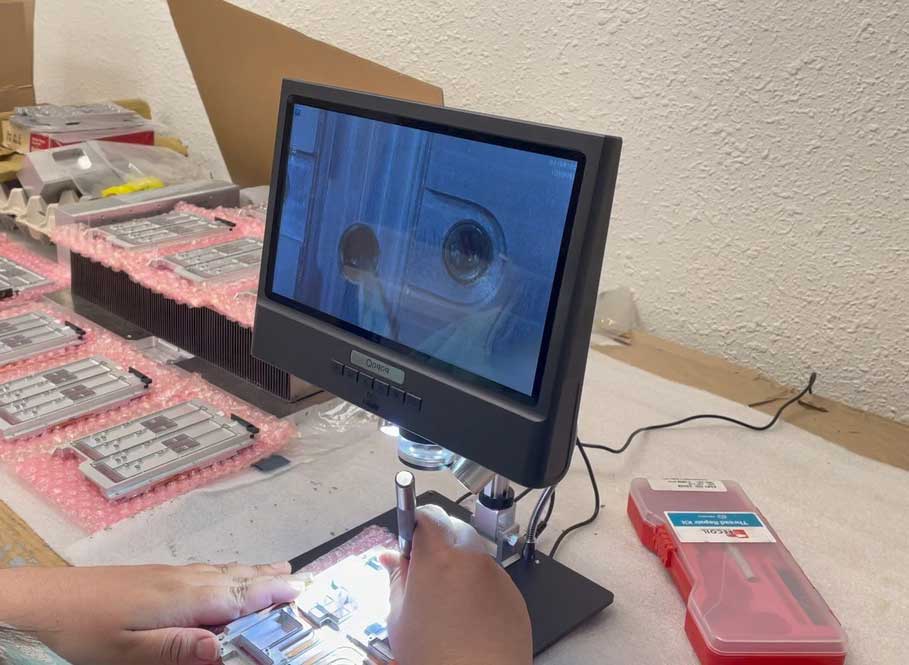

Refers to the stage of Inspection performed on CNC machined parts by the Cooling Source’s team of quality control experts. These quality control experts use height gages, microscopes, 2D projectors, micrometers, and coordinate measuring machines (CMM) to guarantee that parts meet client specifications.

At last, Cooling Source CNC Precision Machining is a high-quality CNC machining service supplier. We have a comprehensive quality management system in place, and our facility is ISO 9001:2015 quality certified.

Contact us to discuss your project with our specialists to ensure you obtain high-quality machined parts.