What is the production method for brazing?In order to combine two pieces that fit closely together, filler metal is heated to a fluid temperature and distributed evenly. Compared to welding or soldering, brazing enables a firmer connection. A solid, sealed junction is created when the molten filler metal joins the base metal.

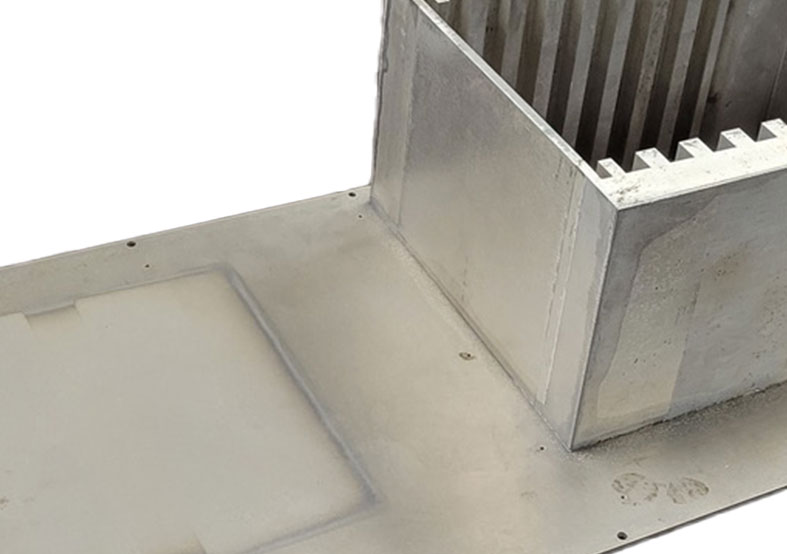

Precision CNC machining vacuum brazed parts made in the USA involves using advanced computer-controlled machinery to create precise and accurate parts and components that are then brazed using a vacuum brazing process. Vacuum brazing is a process that uses a vacuum environment to bond two or more metal parts together using a filler metal that melts at a lower temperature than the base metal.

The precision CNC machining and vacuum brazing process for parts made in the USA typically involves several steps, including:

2. Material selection: Once the design is finalized, the appropriate materials are selected based on the specific properties required for the part and the vacuum brazing process.

3. CNC machining: The CNC machining process involves using advanced machinery, such as CNC lathes and mills, to cut and shape the metal parts into the desired shape and size. This process may include drilling, milling, turning, and grinding.

4. Cleaning: After the CNC machining process is complete, the metal parts are thoroughly cleaned to remove any debris or contaminants.

5.Vacuum brazing: The vacuum brazing process involves placing the metal parts in a vacuum chamber and heating them to a temperature below the melting point of the base metal. The filler metal is then introduced and melted, forming a strong bond between the metal parts.

6. Finishing: After the vacuum brazing process is complete, the part is finished to remove any rough edges or burrs and to give it a smooth, polished surface.

Benefits of precision CNC machining vacuum brazed parts made in the USA include:

1. High strength: Vacuum brazing produces a strong bond between the metal parts, resulting in a part that is highly durable and able to withstand a range of environmental conditions.

2. Precision: CNC machining allows for high levels of precision and accuracy, resulting in a part that meets tight tolerances and specifications.

3. Versatility: Vacuum brazing can be used to bond a wide range of metals, making it suitable for a variety of applications.

4. Cost-effective: Vacuum brazing is a cost-effective alternative to other bonding methods, such as welding or soldering.

Precision CNC machining vacuum brazed parts made in the USA are commonly used in a variety of industries, including aerospace, automotive, and medical. They are often used to create parts and components that require high strength, precision, and durability, such as heat exchangers, turbine blades, and medical implants.

|

|

November 28, 2017