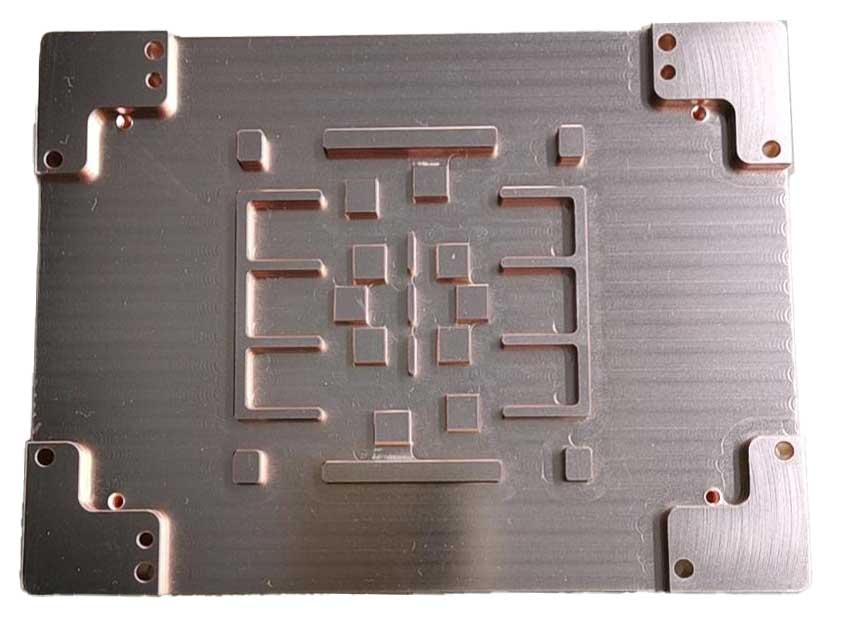

CNC Machining

Cooling Source Manufacturing is a CNC precision machining manufacturer based in Silicon Valley, California, with state-of-the-art CNC equipment. We provide custom 3-5 axis CNC Milling to small, medium, and prominent multi-Industry leaders. Our highly qualified AS0-9001, ITAR-registered plants can simplify or complex any custom design. We provide inspection reports and offer material traceability, certifications, and compliance certificates.

We offer rapid prototyping, small-batch machining, and high-volume production. Consequently, we are committed to providing you with outstanding custom CNC machined parts and Cooling Source services at competitive prices with a short lead time per specifications. You can rely on Cooling Source Manufacturing for your custom metal and plastic parts needs.

What is CNC Milling?

CNC Milling is a manufacturing method of cutting metal or plastic material blocks with machine tools. The cutting tool rotates, and the part is fed horizontally or vertically against the cutting tool. Sometimes, the part remains fixed, and the rotating cutting tool is fed horizontally or vertically. Thereby cutting off redundant materials and obtaining final parts meeting the size requirements on drawings.

CNC milling essentially consists of rough and fine machining.

Rough machining consists of deep-cut materials and removing excess materials. Therefore, removing as much material as possible in a shorter time is a goal to improve production efficiency. After rough machining, the parts’ precision and surface quality is usually not tolerable.

The most crucial consideration of machining is the precision and surface quality of the parts instead of the cutting quantity.

When some CNC machining requires high precision and surface quality, it is necessary to adopt fine machining to improve the accuracy of parts by reducing the cutting quantity. The primary purpose of lowering cutting quantity is to reduce cutting force and make the deformation of parts in a controllable range; The cutting heat is reduced to minimize the thermal deformation of the parts, and the tool wear is reduced to ensure the machining accuracy and surface quality of the parts. After fine machining, the surface quality of final machined parts can reach Ra1,6µm, and under certain conditions, it can even reach ra0.4um, close to the mirror finish.

Advantages of CNC Mil

High manufacturing precision and sustained machining quality.

CNC Milling has strong adaptability as well as holding tight tolerances.

CNC machines can manufacture parts with complex curved shapes and 3D models by introducing 4-axis or 5-axis CNC machines.

CNC milling can conveniently handle multiple processes, such as drilling, reaming, tapping, trenching, etc., after one-time clamping and positioning. It can effectively guarantee tolerances to finish manufacturing a part at one time.

CNC Milling builds a good foundation for production automation. Robot arms could be introduced to achieve production automation purposes and decrease production costs when large parts need to be made by CNC machines.

Our Partners:

ambayarea.com

thomasnet.com

Our Contact Us:

Email Us